[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9

[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9

Fa'amatalaga

VAVETali

VAVEUpusii

VAVETilivaina

SAUNIUNE E FA'A'AI FA'ATA'U

10000+ SKU ile faleteuoloa

Matou te tautino mo mea RTS:

70% mea na avatu i totonu ole 5 aso

80% mea na avatu i totonu ole 7 aso

90% mea na avatui totonu ole 10 aso

Oka tele, fa'amolemole fa'afeso'ota'i le au'aunaga fa'atau

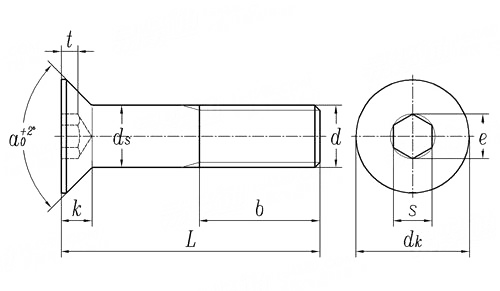

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Pitch | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | tol.(+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L>200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Max=Numera | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Max=Numera | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Nominal | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Max=Numera | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Fa'amatalaga fa'amatalaga

O mea fa'apipi'i malosi maualuga o le a maua ai le mafiafia pe a fa'a'umea. Manaomia le gauai faapitoa.

O le fa'aleagaina o le hydrogen e masani ona fa'aalia i le tuai ona gau i lalo o le fa'alavelave. O loʻo i ai vaipuna taʻavale, fufulu, sikulima, puna o laupepa ma isi vaega uʻamea, i ni nai itula talu ona malepe le faʻapotopotoga, o le gau o le 40% ~ 50%. I le faagasologa o le faʻaaogaina o vaega faʻapipiʻi cadmium o se oloa faʻapitoa, sa i ai le gau gau, ma o se faʻafitauli autu a le atunuʻu na foia ma faia ai se faiga faʻamaʻi faʻamaʻi. I le faaopoopo atu, o loo i ai nisi embrittlement hydrogen e le faaalia tuai gau gau, e pei o: electroplating tautau (ua uaea uʻamea, uaea apamemea) ona o le tele o taimi o le electroplating ma pickling plating, hydrogen penetration e sili atu ona ogaoga, e masani ona aliali mai i le faaaogaina o se gaugau o le a tupu brittle gau mea tutupu; O le mandrel o se fana, ina ua mavae ni nai taimi o chroming, na pau i lalo ma gau; O nisi vaega ua tineia (tetele i totonu) o le a ta'e pe a pikiina. O nei vaega e matua'i fa'afefeteina ma ta'e e aunoa ma se fa'alavelave i fafo, lea e le mafai ona toe fa'aaogaina e toe fa'afoisia ai le malosi muamua e ala i le dehydrogenation.

O le maualuga o le malosi o meafaitino, o le sili atu lea o le faʻaogaina o le hydrogen embrittlement. Ole manatu fa'avae lea e tatau ona fa'amaninoina e tekinisia togafitiga ile fa'apipi'iina ole fa'asologa ole fa'asologa ole eletise. O u'amea e iai le malosi fa'amalosi σb>105kg/mm2 e mana'omia e tulaga fa'ava-o-malo e tatau ona fa'atatau i le fa'amamafaina muamua ma le fa'amama fa'ama'i fa'ama'i. E mana'omia e le kamupani vaalele a Farani se togafitiga fa'ama'i fa'ama'i mo vaega u'amea e maua ai le malosi σs>90kg/mm2.

Ona o le fetaui lelei i le va o le uʻamea malosi ma le maaa, e sili atu le faʻaogaina ma faigofie e faʻamasino ai le faʻaogaina o le hydrogen embrittlement lagona o mea e ala i le faigata nai lo le malosi. Ona o se oloa atoatoa ata tusi ma machining faagasologa e tatau ona faailoga i le maaa uamea. I le electroplating, na matou iloa ai o le maaa o le uamea i le HRC38 na amata ona faʻaalia le lamatiaga o le gau o le hydrogen. Mo vaega e maualuga atu i le HRC43, e tatau ona iloiloina le dehydrogenation pe a uma ona faʻapipiʻi. A oʻo i le maaa e tusa ma le HRC60, e tatau ona faʻatinoina togafitiga faʻamaʻi i le taimi lava e maeʻa ai togafitiga, a leai o le a taʻe vaega uamea i totonu o ni nai itula.

afifiina

Faatatau ia tatou

* O le ata o loʻo i lalo o loʻo faʻaalia ai fefaʻatauaiga eseese incoterms. Fa'amolemole filifili le mea e te mana'o ai.

O'OGA FA'AVAE FA'AVAE

Lelei Muamua, Saogalemu Faamaonia

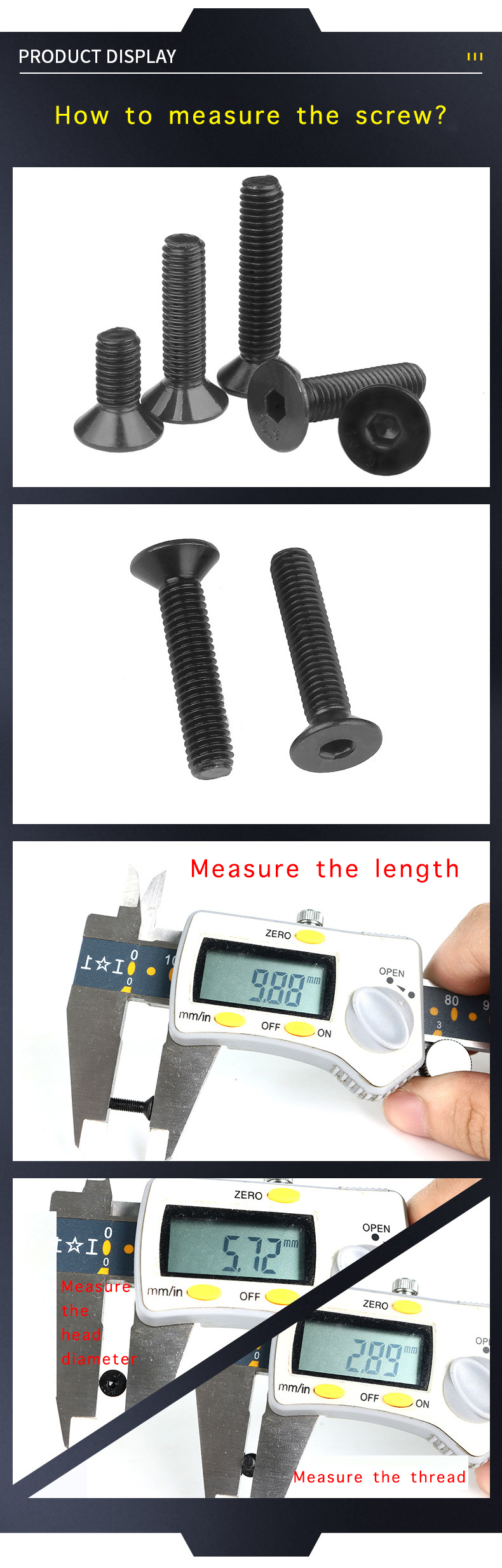

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9 Ata Fa'aalia](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-1.jpg)

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-1-300x300.jpg)

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-3-300x300.jpg)

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-4-300x300.jpg)

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-6-300x300.jpg)

![[Kopi] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-5-300x300.jpg)